ERNiCrMo-3 Nickel Ingxubevange yocingo oluqinileyo (ye-MIG/TIG Welding)

MIG vs TIG Welding: Umahluko Main

Umahluko omkhulu phakathi kwe-MIG kunye ne-TIG welding yi-electrode abayisebenzisayo ukudala i-arc.I-MIG isebenzisa ucingo oluluqilima olusetyenziswayo olufakwa kumatshini kwiweld ngelixa i-TIG idibanisa isebenzisa i-electrode engasetyenziswayo.I-TIG welding iya kusebenzisa intonga yokuzalisa ebanjwe ngesandla ukwenza ukudibanisa.

I-TIG Welding: Izibonelelo kunye nezicelo

I-TIG-oko kukuthi, i-tungsten inert gas-welding iguquguquka kakhulu, ivumela iingcali zoshishino ukuba zijoyine uluhlu olubanzi lwezinto ezincinci kunye nezincinci.Isebenzisa i-electrode ye-tungsten engasetyenziswayo ukutshisa isinyithi kwaye ingasetyenziselwa okanye ngaphandle kokuzaliswa.

Xa kuthelekiswa ne-MIG welding, icotha kakhulu, ihlala ikhokelela kwixesha elide lokukhokela kunye neendleko ezinkulu zemveliso.Ukongeza, iiwelders zifuna uqeqesho olukhethekileyo ukuze baqinisekise ukuchaneka okuchanekileyo kunye nokuchaneka.Nangona kunjalo, ikwabonelela ngolawulo olukhulu ngexesha lokusebenza kwe-welding kwaye ivelisa iiwelds ezinamandla, ezichanekileyo, kunye ne-aesthetically ekholisayo.

I-MIG Welding: Izibonelelo kunye nezicelo

I-MIG—okt, i-metal inert gas—welding idla ngokusetyenziswa kwizinto ezinkulu nezingqindilili.Isebenzisa ucingo olusetyenziswayo olusebenza njenge-electrode kunye nezinto zokuzalisa.

Xa kuthelekiswa ne-TIG welding, ikhawuleza kakhulu, ibangele amaxesha amancinci okukhokela kunye neendleko eziphantsi zemveliso.Ukongeza, kulula ukufunda kwaye uvelise ii-welds ezifuna kancinci ukucocwa kunye nokugqiba.Nangona kunjalo, i-welds yayo ayichanekanga, yomelele, okanye icocekile njengaleyo yenziwe yimisebenzi ye-TIG ye-welding.

Isicelo

Ilungele ukuwelda kwe-nickel-chromium-molybdenum alloys, njl., kwaye ingasetyenziselwa ukuwelda kwezinto ezingafaniyo okanye enye i-welding ye-surfacing surface.

Ukwakheka kweekhemikhali zocingo lweWelding(Wt%)

| Umzekelo | Ukwakhiwa kweekhemikhali zocingo lwe-Welding(Wt%) |

| ||||||||

| C | Mn | Si | Cr | Ni | Mo | P | S | Cu | Okunye | |

| I-ERNiCrMo-3 | 0.006 | <0.14 | <0.13 | 20.69 | 66.29 | 8.25 | - | - | - | Fe:0.61 Nb:3,49 |

Ukusebenza kwemveliso

| Imodeli esemgangathweni ethobelayo (elinganayo). | Umzekelo weempawu ezibonakalayo zentsimbi egciniweyo (kunye ne-SJ601) | ||

| GB/T15620 | AWS A5.14/A5.14M | I-Tensile StrengthMPa | Elongation% |

| SNi6625 | I-ERNiCrMo-3 | 780 | 45 |

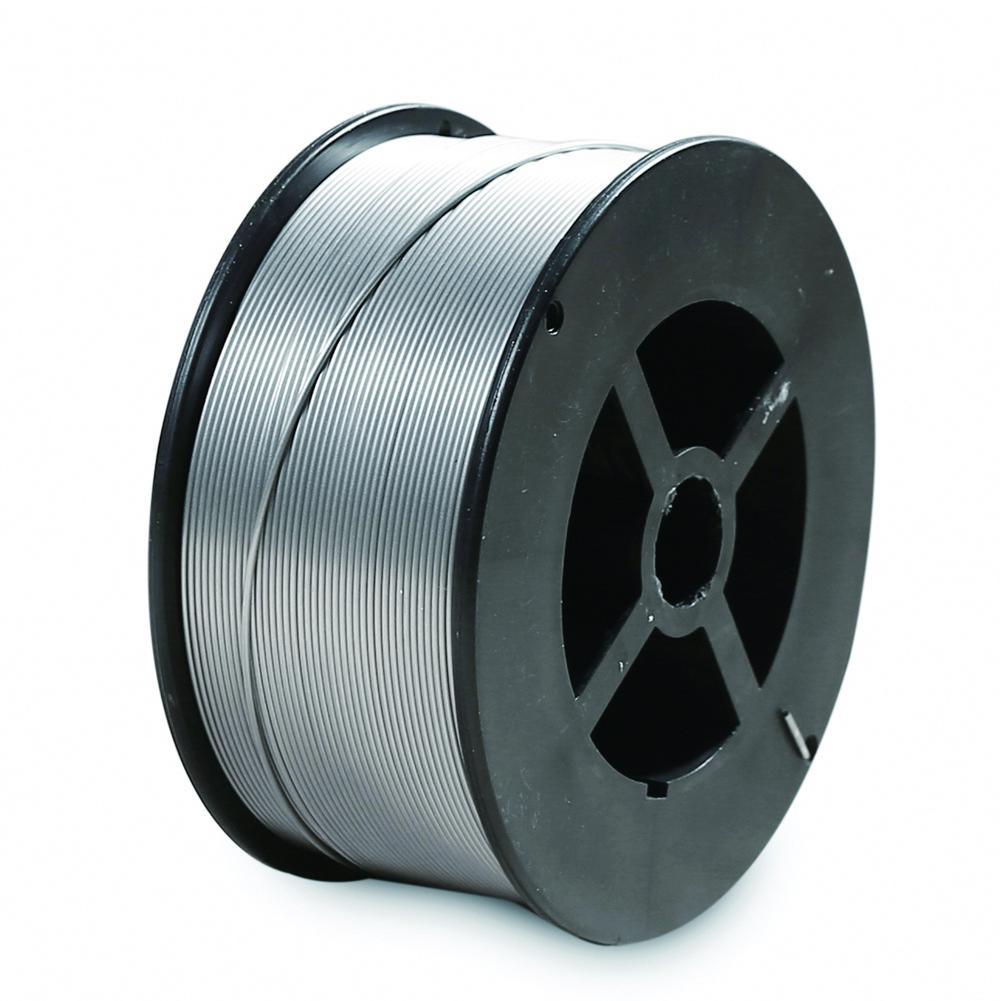

IMig Product Specifications

| Idayamitha yocingo | ¢0.8 | ¢1.0 | ¢1.2 |

| Ubunzima bephakheji | 12.5Kg / iqhekeza | 15Kg/iqhekeza | 15Kg/iqhekeza |

Inkcazo yeMveliso ye-TIG

| Idayamitha yocingo | ¢2.5 | ¢3.2 | ¢4.0 | ¢5.0 |

| Ubunzima bephakheji | 5Kg/ibhokisi yeplastiki, 20Kg/ibhokisi (Inebhokisi zeplastiki ezi-4 ezincinci) | |||